Updates:

- Warehouse Update #27: Dec 2021 placeholder

- Warehouse Update #26: Nov 2021 Kitchen- Part 0, and getting ready for Thanksgiving

- Warehouse Update #25: Oct 2021 Refinishing the living room floor and living room setup

- Warehouse Update #24: Sept 2021 Loft gets sanded and varnished

- Warehouse Update #23: Aug 2021 A break in the action

- Warehouse Update #22: July 2021 Heat pump installed

- Warehouse Update #21: June 2021 The arrival of Summer

- Warehouse Update #20: May 2021 Garden Time

- Warehouse Update #19: April 2021 Siding! We’ll miss you, old friend Tyvek (but not all of you)

- Warehouse Update #18: Mar 2021 Goodbye, Space Bear

- Warehouse Update #17: Feb 2021 Drywall and paint in loft area

- Warehouse Update #16: Jan 2021 More drywall

- Warehouse Update #15: Dec 2020 Drywall, drywall and- zzZZZzz…. oh, sorry, I fell asleep- more drywall

- Warehouse Update #14: Nov 2020 We’re in!

- Warehouse Update #13: Oct 2020 Moving in!

- Warehouse Update #12: Sept 2020 Propane and more work on unfinished projects

- Warehouse Update #11: Aug 2020 Shower, Front Steps, Washer/Dryer

- Warehouse Update #10: July 2020 The four P’s- Plumbin’, Poopin’, Porch, and Pickin’

- Warehouse Update #9: June 2020 Air handler, Poison Ivy (continued), Dog Ramps and Camp Time

- Warehouse Update #8: May 2020 Moving, Snowing, Windows and Doors

- Warehouse Update #7: April 2020 Wiring, Spray foam, and a new visitor

- Warehouse Update #6 : 31-Mar-2020 More exterior sheathing, freak snowstorms and COVID-19

- Warehouse Update #5 : 09-Feb-2020 Lofty Goals

- Warehouse Update #4 : 18-Dec-2019 Raise the Roof

- Warehouse Update #3 : 19-Nov-2019 Back Wall, featuring Ed D

- Warehouse Update #2 : 06-Oct-2019 Asbestos Removal

- Warehouse Update #1 : 15-Sep-2019 Getting Started (AKA The Water is Orange!)

(or scroll down to see previous updates!)

latest-

Warehouse Update #27 – Dec 2021

placeholder.

Warehouse Update #26 – Nov 2021

This month is all about getting ready to host Thanksgiving again like we did in the pre-warehome, pre-COVID days. There’s a lot to do, considering we have no kitchen, no power to the kitchen, and our oven is still sitting out in the warehouse in a box.

First things first, electrical. A lot of electrical for the kitchen. I ran separate circuits for fridge, range, dishwasher, microwave, and outlets. Ran conduit through the basement, from the panel down underneath the kitchen, and then romex up through the floor and walls of where the kitchen will be. A lot of work and a lot of wires.

I’m sure that you’ve been following right along with the progress and remember that there is a temporary wall separating the front half and back half. We’d been living in the unfinished back half while we worked on the front. Now that the front is progressing we moved our living room to the front. We’re about to remove the temporary wall. Here you can see the fridge and sink space set up against that temporary wall, with the future kitchen space and wall on the left-

And now we’ve finally removed the temporary wall, and moved the sink and fridge over against the wall on the left will they will be located now and in the future when the kitchen is complete-

Pretty incredible to be able to see from the rear of the place to the front, with some things finally getting into place. Been separated in half for over a year!

We’re supposed to have 12 people for Thanksgiving so I set to work setting up some different walls for privacy for (people to sleep) with whatever materials I had laying around. Pretty ghetto to say the least but didn’t put too much time into it-

and my sister will be staying at our camp so I covered some of the bare walls (just insulation covered with plastic) up in the loft with some new pine shiplap-

Jennie got to work moving records into the living room and setiing that up as well as moving in and organizing all of the dishes that we had stored in boxes, getting ready for Thanksgiving dinner-

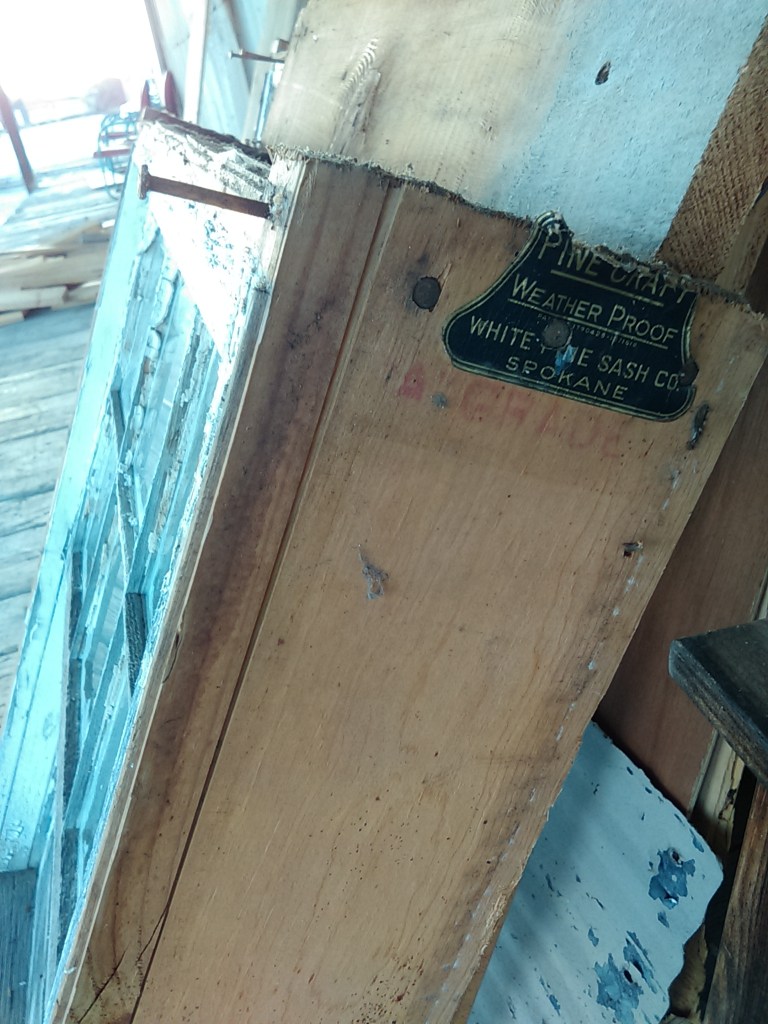

In other news, I found this giant General Mills sign in the crawlspace under the warehouse. It’s probably about 16′ long in total. The previous owner mentioned that the building used to be a General Mills feed store way back in the day. That prompted me to contact General Mills and they actually had some information about our store and an actual photo of the front of our warehome from 1956!

That image on the lower right is the warehome. On the left side of the image is the loading dock, clear as day! Seeing that big picture window there explains a lot about some of the structure on that front wall. There’s a big 6×6 beam that went all along there. Pretty cool stuff.

Unrelatedly, man in Castelton tries to burn 13 propane tanks, 4 oxygen tanks, and 2 gas powered chainsaws. Believe it or not, this resulted in an explosion:

Lastly, I just CAN NOT pass up photoing a good public misspelling. Sorry for the inconvience!

(the best part is that it’s now like actually Spring 2023 when I’m finally getting around to updating this posting for Nov 2021… and they are STILL using this sign)

Warehouse Update #25 -Oct 2021

After a lot of work the sheetrock on the ceiling was finally finished up- hung, taped and mudded, and primered. At some point I’ll go back and add trim along the wood beams and clean all that up and finish the front half. That will probably involved moving some things like the living room to the back of the warehome again, but for now we can get moved from the back of the house into the front and start making some progress on the back side of the house.

Was able to finally remove all the temporary scaffolding that I’d built to work on the ceiling. Nice to finally see it all opened up after a long time of having sort of a multi-level setup with the scaffolding. Now that the scaffolding is out of the way and the construction debris cleaned up, it’s time to refinish the floors.

All in all I think I sanded that floor for 11 straight hours. It had a lot of uneven-ness in it. But was definitely pleased with the final result after three layers of the satin varnish.

And then we got to work on setting up the living room. I think we’re going to need a bigger TV… the old 52″er looks pretty small in there. Good enough for now…

On the outside, Ed came over once again and helped me get cracking on putting up siding on the side of the building-

Still not quite sure what to do around the electrical. Might end up siding wood over the metal.

Unfortunately, we seem to have a small leak in the ceiling above our bedroom. Ruined my favorite shirt. Oh well. Hung a paper towel under it for now to catch the early leaks. Will definitely need that fixed before putting up the sheetrock there. Suppose it’s good it happened before the ‘rock was up. Been a few small leaks in that area from when the roof was repaired. The roofing co has been working their way through fixing them.

In other news, just found these freakishly large mushrooms growing the yard at camp. Big as my hand! I think something was snacking on them.

Warehouse Update #24 – Sept 2021

In big warehouse news this month, the loft gets sanded and 3 coats of varnish.

Never sanded a floor before. If you’re thinking about doing it, I highly don’t recommend it. I researched some stuff about sanders before renting, and it sounded like a random orbital would do the job. So, 45 minute drive each way to Glens Falls Home Depot to rent one. Then, finding out that it won’t cut the mustard, so another trip to and fro to get a drum sander. Many many hours and several breaker trips later, it was done.

I will say I was very pleased with the result. We got all the T&G 2×6 reclaimed flooring for the loft from a guy on craigslist who pulled it out of a building he was tearing down, for cheap. Hauled it on my tiny trailer from Burlington to Fair Haven- 1.5 hours- wobbling all over the road. 16+ ft lengths on an 8ft long trailer made for a very unstable ride, esp on old Route 22A (the highway of death). But I made it. With sanding and varnishing this old wood shows a LOT of character and color-

In other news, a cat started sleeping on our porch. I’d find traces of his dirty little stray cat self on the outdoor furniture but never spotted the little vagrant. Turns out he was getting up just before Jen did each morning. I doubt it being a coincidence. Busted here on camera getting up at 6:08. Jennie gets up about 6:30. I get up… later… Clearly this cat understands the importance of a good stretch before moving about.

OSB prices coming back down? Hopefuly for good. They’ve been on a rollercoaster ride, up to about $45/sheet at one point. For something that was costing about $7/sheet a year or so ago-

Bought this Honda NX650 Dominator from my dad. Great bike. One of the few that fits my tall sasquatch frame. Very comfortable for me and tons of power. The very first bike I learned to ride on was my dad’s old Honda NX650. Actually a different one than this. He sold it, had a diff bike, then got another. Now this one is mine. You don’t see a lot of these around. One year only bike, made in 1989. Way ahead of it’s time, this is “adventure bike” in an era where there wasn’t such a thing as adventure bikes-

And, lastly, two funnies:

100% “Vermont Maid” syrup! “THE TASTE NEW ENGLAND LOVES”!!!!!! I love that it’s “Original” flavor. Do they also have a “Dark Amber” flavor?

And, yes, the back of that truck says “By By Mother”. Almost got in an accident getting that photo but it was worth it. I can’t make this stuff up.

Sitting on the loading dock, enjoying a beautiful late Summer evening…

Warehouse Update #23 – Aug 2021

Looking back through the month’s photos for August, it looks like there was no new construction on the warehome. Sometimes you’ve just gotta have some down time.

Went on a trip to buy a juke box and ended up buying two! Couldn’t believe that two would fit in the back my my Honda Ridgeline but indeed they did with a lil room to spare. They are HEAVY! Now to set Jennie to work loading them up with good records-

I spent a little time moving some bikes around in the warehouse and lining them up. There were a lot just kind of scattered randomly about. Here is a sample (yeah, there’s def more than this… and, yes, its a sickness…) :

Went to view some OLD bikes- mostly Indians- at a pre-auction viewing. You think my bikes are old! Cool stuff but not really my thing. They had one small Honda that sold for way too much. Maybe I should put some of my bikes up for auction?

Back at camp- baby Mr Toady! I can’t be sure that he’s of the same lineage, but the resemblance is uncanny-

Unfortunately, I don’t think our brussel sprouts are going to hit the finish line. It’s late August and they are only the size of maybe small marbles. And, just to round things out- butterflies, and Jack. His old man face is getting so gray…

Warehouse Update #22 – July 2021

The big happening at the warehome this month was getting a heat pump installed. Our primary motivator here was that in addition to heat in winter it does AC for the summer months and with just one big open space it didn’t seem like it would be too difficult to cool the place with a single unit at the rear of the warehome. Vermont also offers some discounts for doing it.

First I needed to side the rear of the building where the unit would be located so that all of the plumbing for it could go through the siding. On the interior sheet rock needed to be hung where the unit would be mounted. So both inside and outside, we did the bare minimum to allow the thing to be installed. Outof site and in the crawlspace I ran 1/2″ metal conduit and wire to where it would be located outside to save a bit of money on the installation, which was done by professionals that have to be approved by Vermont to get the refund. We went with Maple Leaf Mechanical, located right here in Fair Haven- just down the street actually. They were a young crew and did a great job before, during, and after the install. Made sure to stop by and walk me through how to use all the controls after the install. Good folks.

Before:

After (there is actually a cover that was installed over all that piping running up the building, that I didn’t get a photo of):

The other big happening is ants. Carpenter ants. We’ve been seeing them popping up here and there, nothing major but a steady trickle of them. As I started reading up on them I found that they were drawn to wet areas. Wouldn’t you know it, I’d just noticed that leak around our chminey last month. Upon further investigation I was able to find a steady trail of them coming in on a beam in the warehouse, through a crack in the wall and then tunneling up into the spray foam around the chimney where it was damp. Like a carpenter ant super highway! So, I set about setting up some ant bait that they take back to their nest to kill the colony (sorry, ants… but not very sorry).

As you can see I bought just about everything Amazon had to offer related to killing ants… only to find out afterward that carpenter ants are only attracted to a very specific sort of bait. So most of it is still sitting in the box, unfortunately.

Back at camp, the garden is coming in nicely. But we got a pretty bad infestation of cabbage worms. They like to eat a lot of things we planted- cabbage, broccoli, maybe brussel sprouts? Thankfully there is some natural bacteria type stuff you can spray that knocks them out pretty well- but they do quick work.

I finally got all the supplies I needed for the fence and Ed and I got to work getting that all installed. Looks great.

Afterwards we were both sitting around the fire and heard quite a ruckus coming from the trees. Checked it out and the trees were full of turkeys. Unfortunately it was getting dark and they were way up there so I couldn’t get any photos but they were making a lot of noise, even breaking branches.

In other news, not a lot to report this motnh. Dug up a slamander at the warehouse while levelling out some area around the lean-to at the end of the building-

and captured this image of the Meatboy lounging in the yard and enjoying the late day sun. He sure is enjoying enjoying his golden years. One of my favoritte photos-

Warehouse Update #21 – June 2021

Looking back through my June pics, it’s good to see more relaxing happening and less working.

At the warehouse, we got the bird feeder out and found some leaking around the flashing of our furnace chimney. The woodpecker’s love to come-a-knockin’ in the spring. It’s actually pretty annoying-

And at camp, the herbs and early veggies are coming in nicely. Lettuce, swiss chard, herbs, etc-

Mostly other random news to report this month. But perhaps most importantly- the return of Mr Toady! Every summer he reappears near our front steps. Summer is officially here.

And another sure sign of the weather warming, nature is popping all around us. Mice have infiltrated everything during the colder months. This year they’ve chosen to nest in the dash of the SS Mouse Terd (aka our pontoon boat). Usually the like they live well and bimini top. They’ve also chosen a tight spot in the battery compartment of one of my trail bikes-

A robin has chosen to take up residence and nest in a broken window in the warehouse. I don’t think she thought this through. Every time the sun shines hot I think her and her babies are baking. I see them in there with their heads up and their mouths wide open-

And a pair of snakes (Jennie’s favorite) is making the literal beast with two backs-

And I got to do some crusing on the old CL100 around the area of our camp in Benson, taking in some of the incredible Benson scenery by the mill, Sunset lake, Castleton River, and then down around the locks near Whitehall. A few photos along the way-

Warehouse Update #20 – May 2021

Weather’s warming up and so are the outdoor projects. Nice to be outside again after a long winter of sheetrocking.

Got the front porch sided up and doors and windows installed-

Moving our way across the ceiling with the sheetrock, from front to back. We’re still living in the rear half with a temporary wall between front and back. Rear is the stuff with spray foam showing still, and the front is the rock’d portion. Almost half done, and sliced my finger cutting a sheet pretty badly. The front area under the loft (where the plants are) is now all rock’d, mudded and primed with white paint. Nice to finally at least have some section done (altho still a bit of a mess)-

Getting our garden area started at camp. We mowed maybe an acre in the upper field and started putting up a fence- just a section or two for now- COVID has apparently shut down the pressure treated lumber scene- but will eventually go across this portion of field on the edge of the garden. Picked up a few starter plants and started planting some seeds and getting a few sprouts. The soil is pretty sticky clay so it’ll be an experiment. We have one section in the ground and then one raised bed filled with garden mix. We also started a few planters near the main camp building with flowers and herbs. And we had some perennials that we transplanted from our place in Essex that are coming back nicely (the purple flowers there, I forget their name)-

And in other news, got that CT90 running and out for a test run. “Old Yell’r”. Old tires and no brakes!

Warehouse Update #19 – April 2021

I’ve not done any updates in quite some time. This entry is for Apr 2021 and here it is in real-time almost summer of 2023. The last two things I’d posted in here were the passing of our dog Mason (Mar 2021) followed by the passing of our dog Jack (Jan 2022- the “future” from the date of this post. Spoiler alert?). Hard to believe two dogs can live out all 17 years each and then pass within one year of each other. Every time I logged back into the site to post some updates it would just tear me up and I couldn’t get past it. But it’s been over two years and I’m finally at a point where the site either needs to be updated again or else it needs to end. I wouldn’t want to disappoint all two people that check the progress here, so here we go again!

I’ll try not to bore you with too may more details and pics of sheetrock. But, there’s a lot of it to do! There’s a lot of months to get through so here goes, speed-round style, maybe?

This month the big deal was siding. Finally got the first batch of siding done after letting the wood dry way longer than it needed to. Board & batten siding, 12″ wide with 2″ battens. The rear side of each board was stained to protect the back. Was really nice to finally be looking at something other than Tyvek siding for a change.

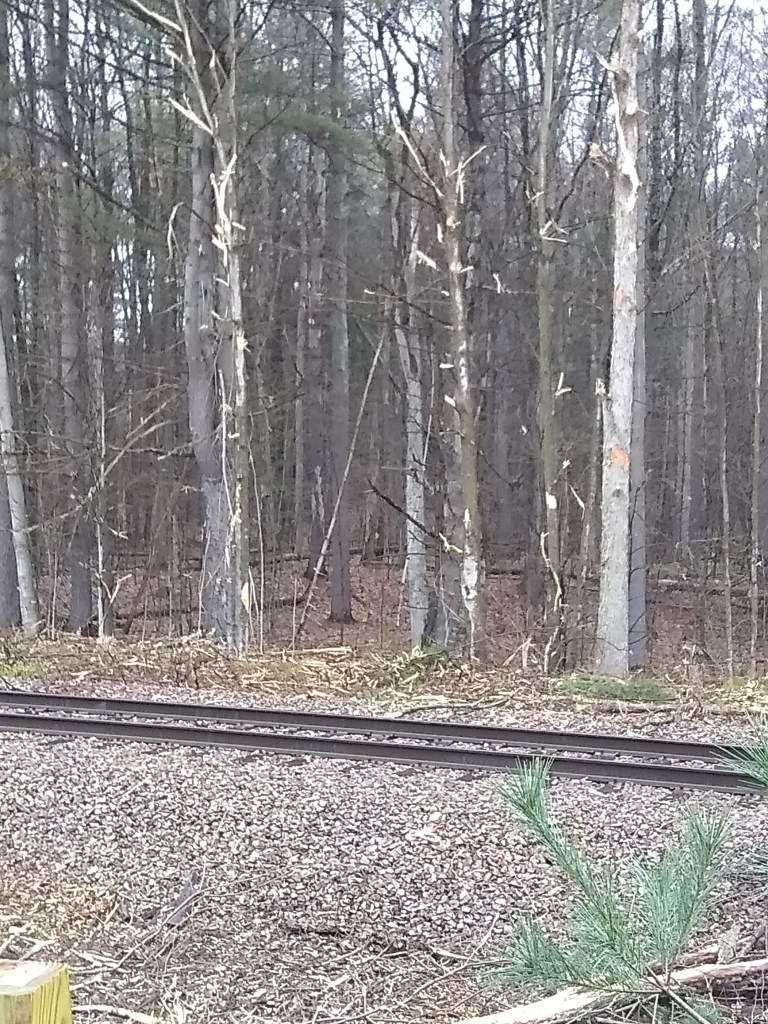

And the other big happening was the railroad blasting down all trees on both sides of the tracks with a giant spinning drum on a big backhoe riding on the tracks. It spewed out debris everywhere and shredded everything in site. Big chunks of wood were bouncing off the house. Not sure how we didn’t lose a window. The pictures don’t really do the destruction justice-

And then in other news… My neighbor Heman gave me an old CT90 K0 as a random gift. Awesome! Needs a little TLC and derusting but a good solid old trail bike. First thing to do is polish and patch up the busted headlight bucket.

And of course it wouldn’t be April without a freak snowstorm or two.

And, lastly, the Meatman and I got out for some exploring in the woods. Probably picked up a tick or two.

Warehouse Update #18 – March 2021

We had to say goodbye to our sweet old dog, Mason, this month. You can read all about his fabulous life and view some adorable photos right here on our blog page.

Warehouse Update #17 – February 2021

More drywall this month. Finishing up with the drywall, mudding and painting up in the loft area. Put up some plastic sheeting to keep the dust down and out of the living area and furnace intakes.

Laid down a few more sheets of OSB on the temporary scaffolding to work off of. We have to keep moving our OSB sheets from area to area because it’s gotten so expensive. You’ll see back in Nov 2020 I was complaining that it was $25 per 1/2″ sheet. It’s gotten now up to $33. And I need 3/4″ (or it it 5/8? I forget…) to walk around on, not 1/2″ (which I guess is actually 7/16″). Thank you COVID.

Other than that, not too much to report. Some drywalled and painted loft pics below.

Warehouse Update #16 – January 2021

Happy New Year! On the warehome front, not much happening. Even less than last month.

In the outer world- we’ve got a new president, COVID still looms large although the vaccines are finally starting to get rolled out. Oh, and almost forgot- there was just a little insurrection at the capitol as it was stormed by thousands of protestors, 6 people died. You know, the usual January stuff.

Oh, and we got a couple juke boxes too! Old 45 records. Fun stuff. I went to look at one and the seller had several there. He showed me another and it was even better than the one I went to look at. I offered to buy both and he gave me a deal too good to turn down. Jen has been busy cleaning records and swapping out old boring and scratched records with better condition and more fun tracks and printing new labels. Hmm… looks like I didn’t have any photos of them in my Jan photos folder- go figure. Maybe next month.

At the warehome, just continued installing more drywall. Now mostly on the ceiling. This is going to be a long boring phase of work. Hang, tape, mud, paint, repeat… I had built some scaffolding in prior months to get started on the ceiling work and now I’ve extended it to span the width of the building so we can work more of the ceiling. Next I’ll have to extend that depth-wise, towards our current living space, over where the kitchen area will be so we can finish that ceiling area up. When that is all complete, it will cover about 2/3rds of the ceiling, and then we’ll need to sand and finish the floors and then swap our current living area into the other end.

Summer will probably hit before that is ready and we’ll probably be back at camp most of the time, which will help with a few projects that will be better to do without anyone in there (like the floor sanding, more drywall sanding, and electrical). It’s been challenging to get the drywall sanded and still keep things clean so we can live in there and also have the furnace running without sucking drywall dust into the furnace. Lots of plastic sheeting. But most of that will be in the Feb update.

Not much else to say. A few pics of the new scaffolding and progress on the drywall-

It seems like slow progress. But did I mention this is a one man job? Getting drywall up onto a 15+ foot ceiling one sheet at a time is a pretty exhausting process. Jen has offered to help a number of times but that scaffolding is pretty dicey. She’s helped me out of a few tough spots where I just ran our of appendages and was doing all I could to keep a sheet balanced in place with one hand, my head, maybe a foot, and trying to get it all screwed in before it crumbled down on top of me.

Our internet is so crappy, you wouldn’t believe how difficult it was just to upload those few pics. *sigh*

That’s it for this month. Until Feb- Stay warm. Keep an eye out for the crazies.

Warehouse Update #15 – December 2020

Should be a brief update for this month. Just installing now what feels like an endless sea of boring white drywall. While it’s nice for a change and to get to this stage, which really shows things are coming together, it’s a lot of the same with what seems like no end in sight. I just need to buckle down and get it down. As much as I dislike installing the ‘rock, I dislike the mudding even more- so I have that to look forward to in the next phase. Not much of a motivator.

Not much to say. A progression of pics of the sea of whiteness-

Mostly walls there, but then I needed to get on with the ceiling. I contemplated bringing in my scaffolding and setting it up and moving it around but decided just to build some temporary scaffolding across the beams that were there. Worked out pretty well and made it a lot sturdier and easier to move around (although to be honest it’s still fairly unsafe and a bit sketchy up there)-

We got one of the porch doors in (a bit crookedly.. but not so bad that I’m going to mess with it- it’s square, anyway) and found some thick wood planks under the loading dock that matched pretty well with the existing dock to finish up the patch leading up to the door-

We got our first big snow of the year, a couple of feet pretty quick just before my birthday. Here you can see that my “covered” dog ramp is really well designed and keeping the snow off exactly as anticipated (uh, not)-

We hung some Christmas lights on the front loading dock. Destined to be re-designated as way-past-Christmas lights-

Little odds and ends… We got our bathroom door painted and hung, got a new kitchen table and grew into our kitchen area a bit more, and finally got our bathroom mirror (after like 3 weeks of waiting on it to be delivered- yay COVID!)

For my birthday I asked for as many battery chargers as people were willing to give me, so I could keep my bikes charged through the winter instead of ending up in the spring with a bunch of dead, frozen, unusable and expensive batteries that need replacing. I came out pretty good and shuffled some bike to get them on chargers. For now, extension cords running all over but soon will wire up some outlets there-

Then, post-birthday, on to Christmas… Made up this holiday meal via toaster oven and microwave as we still don’t have our permanent kitchen set up (new oven is boxed up out in the warehouse). Had a turkey breast, some suspicious looking gray material that was labelled as stuffing (debatable), a Shaw’s discount roll, and some mashed potatoes. We also traded a ham that Jen got (since it’s a bit tricky to cook a whole ham in the toaster oven) to our neighbor for sides of apple sauce, squash, and fudge. Turned out to be a pretty solid meal, considering-

This crazy holiday train rolled right up on us! Man, this was so cool!

And some other random tidbits to wrap up the month of Dec 2020:

Epic COVID beard (this is what happens when you don’t get to leave the house, and no one is coming to visit). I don’t think I intentionally took this, my phone touchscreen was just on it’s last legs and this was one of the last photos accidentally snapped before I got a new camera-

Chicken nuggets- with “real cheddar cheese”- touting 100% chicken, and no fillers? I wasn’t aware there was cheese (real or otherwise) in a chicken nugget. Is cheese chicken? And if so, I guess that makes it not a filler? This makes no sense to me. Thanks goodness it’s gluten free. I would’ve thought there would be gluten in that breading, but I guess it’s 100% non-breaded breading…

The truck continues patiently waiting for it’s turn, at the bottom of the work queue…

Warehouse Update #14 – November 2020

It’s actually Feb now, and I’m just getting around to updating the Nov entry. Falling a bit behind, again…

Started things off with getting our temporary sink plumbed in so we could finally use something other than paper plates and plastic ware. It’s in roughly the vicinity of where the sink will end up so installing the new sink and plumbing for it will be fairly easy. An early look at the temporary “kitchen”:

It’s getting harder and harder to get our dog Mason out through the warehouse and down from the front dock before he looses his bowels or bladder. And it’s becoming increasingly cold so that you don’t want to have to go walk the dogs around the warehouse every time they need to go out. So we built a dog ramp off the back of the house where the rear porch will eventually be. It’s only temporary, as we’re not going to have time to build that rear deck this year anyway and I’m not sure how many years the old pup has left in him anyway. He has a lot of trouble with any type of incline so I built a 16 foot long ramp to give him the gentlest slope that I could. It’s all covered over to keep it from getting too icy or snowy. At the end I cleared some of the brush from behind the house and pulled up several of the railroad ties from the old train siderail that went up against the building where they unloaded grain, and built a decent sized fenced in area. Pups are still getting used to the whole setup and Mason still likes to just go out the door and directly pee on the upper platform without going down the ramp. But we’re hoping he adapts to using it.

I bought some moving blankets and hung them between the living room and the bathroom to make a little temporary (yes everything is temporary! 😉 ) hallway to keep dust from the working area out of the living area-

and built a small counter space for our microwave and toaster oven-

Then got the bathroom walls mudded and primered-

As was mentioned in months prior, we’re putting wood recycled from the attic floor on the bathroom ceiling. It’s all stained and varnished and ready to go in. We put a coat of matching brown paint on the ceiling first to hide any gaps between the boards-

and then we painted the walls a nice shade of light green and decided to do some more tile around the shower to finish things off-

And that’s where we had to call it quits for now on the bathroom work. It’s too difficult to work and live in the same space. There was always grout and drywall dust and whatever else on the floor, sitting on top of cardboard to keep things clean. The space is now useable but still needs the second sink, trim, and some built-ins, which will probably get revisited during the summer while we’re back at camp. Here’s a virtual walk-thru of where we left things-

That pretty much covers the highlights of the month. That bathroom work seemed like it would never end. Lots of detail work that goes into a bathroom.

Some other random moments as we navigated through the month…

The Meatman snoozing on the front dock while I do some work-

$25 for a sheet of 1/2″ OSB, compliments of COVID-19 pricing. When we started the project, it was about $6/sheet. When we had finished up with the sheathing on the exterior it was up to $13/sheet and I was cursing the Home Depot. At the latest trip to the depot it was $25 a sheet. Unbelieveable. Supplies are getting generally harder to get, and you can’t always count on getting what you need when you make a trip to the hardware store, for stuff that you always used to take for granted (pressure treated lumber, OSB, lag bolts, etc)-

Here are the pups relaxing in their new space. Jen has gotten most of her records unboxed-

And that about covers the month of November. Enjoy.

Warehouse Update #13 – October 2020

Well, it’s finally happening- getting too cold for camp and time to close it up and winterize. A couple nights toward the end of the month are predicted to be in the upper teens temperature-wise. Still a lot to do…

Some of the updates here this month are a bit of the same from last and prior months. Several projects are in flight now, progressing slowly and moving closer to completion. I try not to repeat myself on prior updates, but instead just append the latest updates to all projects in the works.

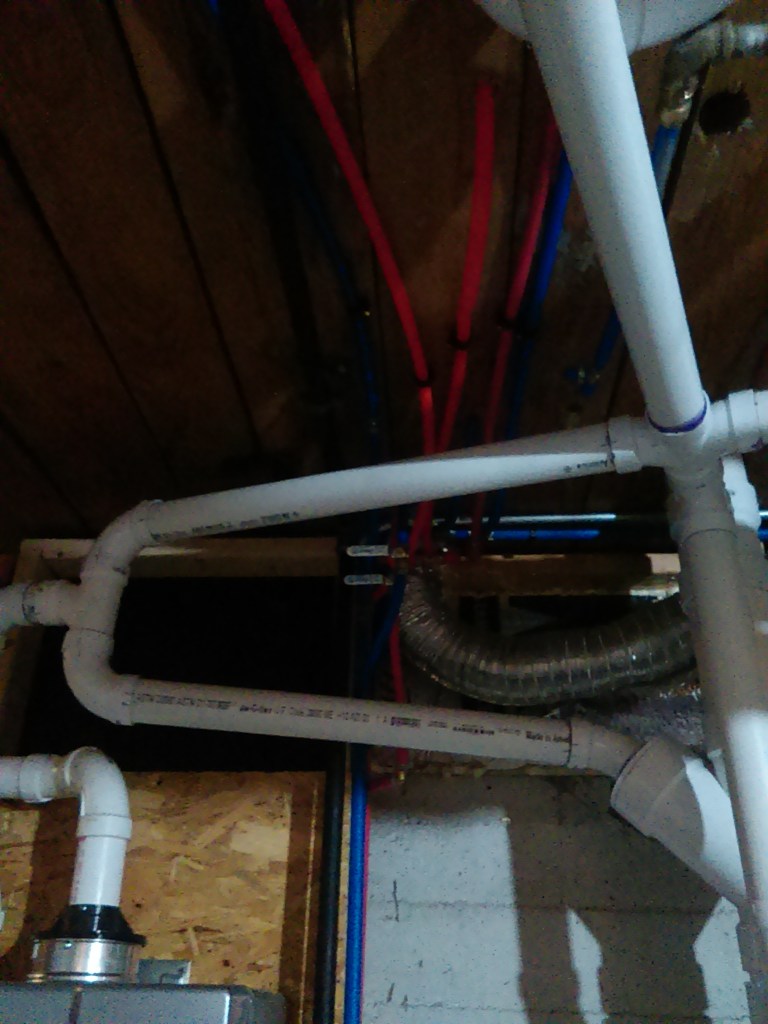

Got the hot water vent installed and the lines all run. Went surprisingly quickly to do the plumbing with PEX and no issues. It all went together very easily and quickly. It reminded me a bit of being a kid again, like Legos or an erector set or something like that. Swearing was at an all time low. Plumbed the whole place in about 4 hours with a couple trips to the hardware store in there. Everything is easily accessible from the basement which makes it nice- easy to work on, easy to access, easy to change if needed as things change.

Our water heater is a condensing unit which is very efficient but produces a very acidic condensate that can’t go directly into your septic and can even dissolve some types of drains like the old iron we’ve got at the bottom of the stack. So the condensate runs down into that little sump you can see below the water heater and into a bunch of acid neutralizing media. Then we had to plumb in a new drain/trap that it gets pumped up into to drain out to the septic.

On the shower front, we finally finished it up. Tiled around the upper area, lines and drains all plumbed in, hot water all plumbed up (hooray!), glass shower door installed. The Flexstone shower kit also had an optional window trim kit that we purchased for the window above the shower. Was so nice to finally take a shower in there. The outdoor camp shower was getting a bit chilly.

At first I was a bit distressed because the shower water was barely warm. Turned out there was some limiter in the shower knob for the temp- so I had to disassemble all of that and then reinstall- what a pain.

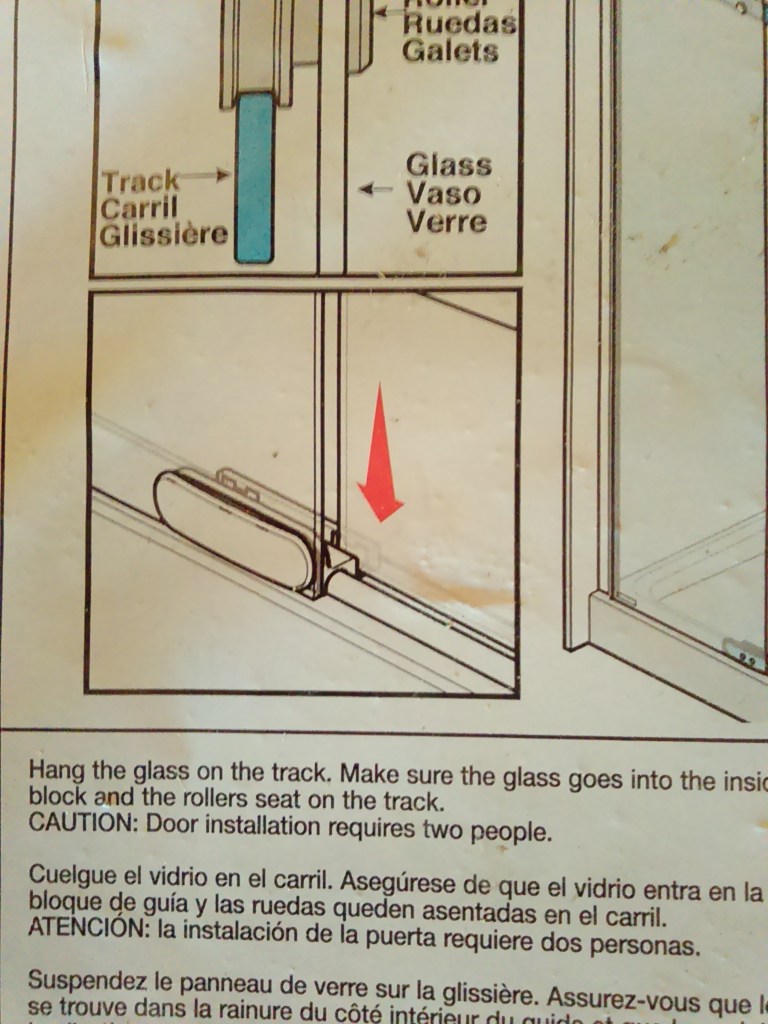

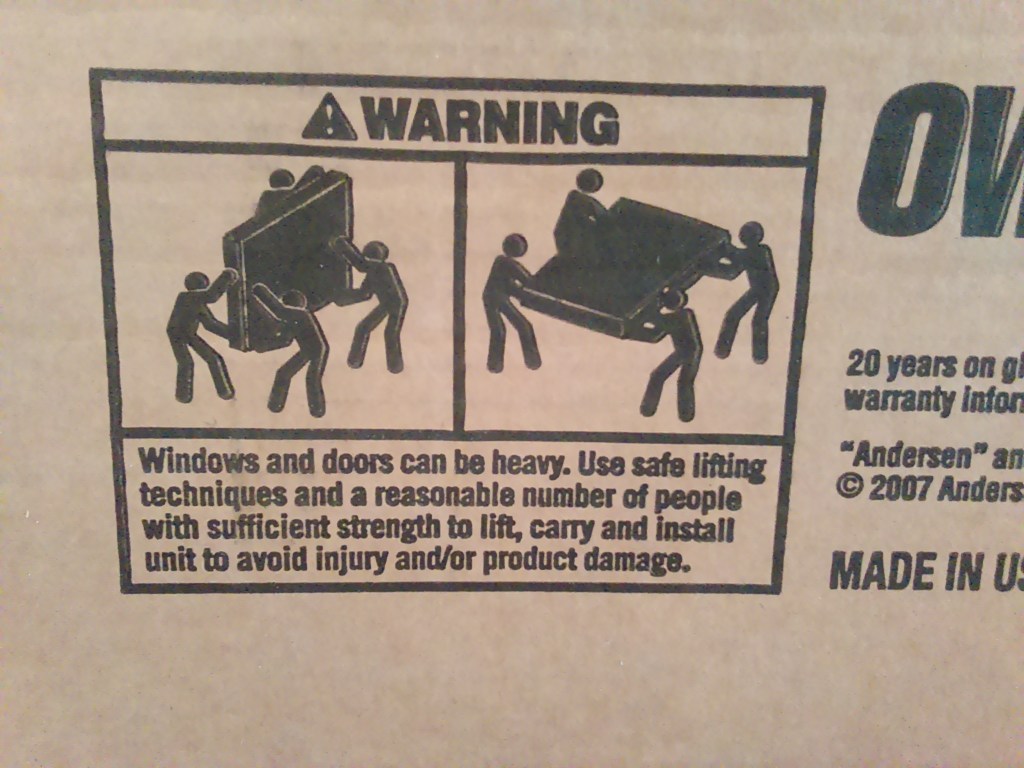

When I was coming out of the store with the glass door it was a bit awkward to get off the cart and into the back of the truck. There was a woman walking by and she asked if I needed a hand. I begrudgingly admitted that I did, and so she assisted by holding the cart while I pulled it off. She mentioned that her and her husband just installed the same door and it slipped off the frame and cracked their new tile, so “be sure and have another person to help when you put that in! It’s heavy!” she said. I chuckled and said ‘sure thing’.

Wouldn’t you know, I dropped that damned door right off the shower frame and onto the tile when I was installing it. My heart skipped a couple beats, maybe temporarily stopped. But I looked down and no broken glass and no tile chips. Phew! Once again, the box warns that multiple people are needed (“CAUTION: Door installation requires two people”)-

The manual said something about it being tempered glass which is very strong but when it breaks it makes a loud noise and breaks into thousands of tiny pieces – “for safety”. Glad I didn’t have to experience that.

We also decided to put up stained boards on the bathroom ceiling, which Jen had stained up last month, and now got to work on sealing them up with some satin varnish-

We’ve got to finish up with the drywall mudding now so that we can get those and the bathroom ceiling fan installed.

While this was all happening we got our roof fully patched and then ends fixed up and redone and re-glued. We’d had a little patch work done previously just to keep things water tight and not leaking, but the half walls at the ends were in rough shape- the rubber was not secured to the sidewalls and the seams were all separated and had been re-glued but were just floating a bit out there. It was functioning but needed work.

The first quote we got was for a new roof just over the living area. I asked these roofers to schedule a time for the job and they never got back to me. So, we later had a second company come for a second opinion and gave us a quote on repairing the entire roof (over the living space and warehouse) and fixing up the floppy mess on the side walls. They said it’ll easily go on another 15 years or more after the patching.

Don’t know how well you can see it in these photos, but here is the sidewall before and after the repair- on the left before the repair its a bit loose and “frumpy”. On the right- after the repair- it’s good and buttoned down-

We installed some new bedroom lights so we wouldn’t completely be in the dark in there. The lights came with lamp shapes- thank goodness the label on the shades informed me to remove the plastic wrap prior to using! I was just about to leave that on there!

We hung most of the drywall on the walls in the bathroom. Really wanted to be completely done with the bathroom prior to move-in because its hard to live and work in the same space. But it just didn’t happen. But at least it’s functional.

Below is the half that we’re going to live in. We got to work cleaning it, moving all the tools to the other side and bagging the mess. You’ll notice the upside down vacuum cleaner which may have gotten kicked when I lost my utility knife (again) and had a small temper tantrum. I don’t know how I can have 10 utility knives yet never be able to find a single one when I need it. I digress, again….

We migrated Jens office setup moved to the new location in the warehome-

and set up a temporary wall to split the space in half for living and construction, to hopefully minimize dust and tool dangers from the construction area-

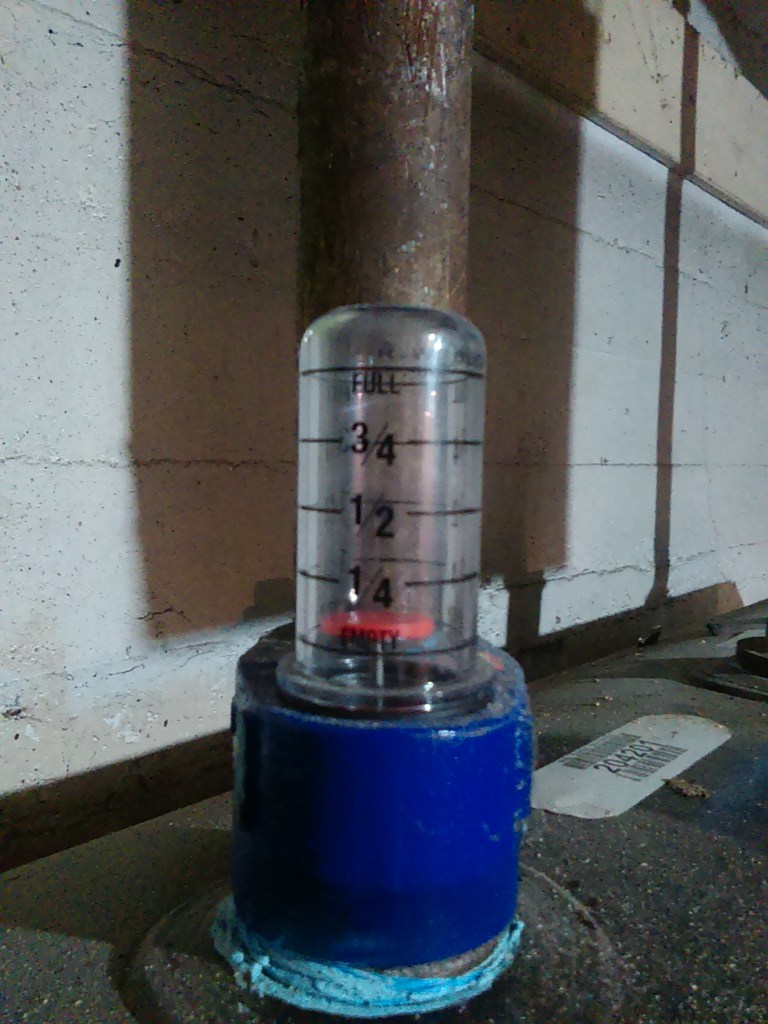

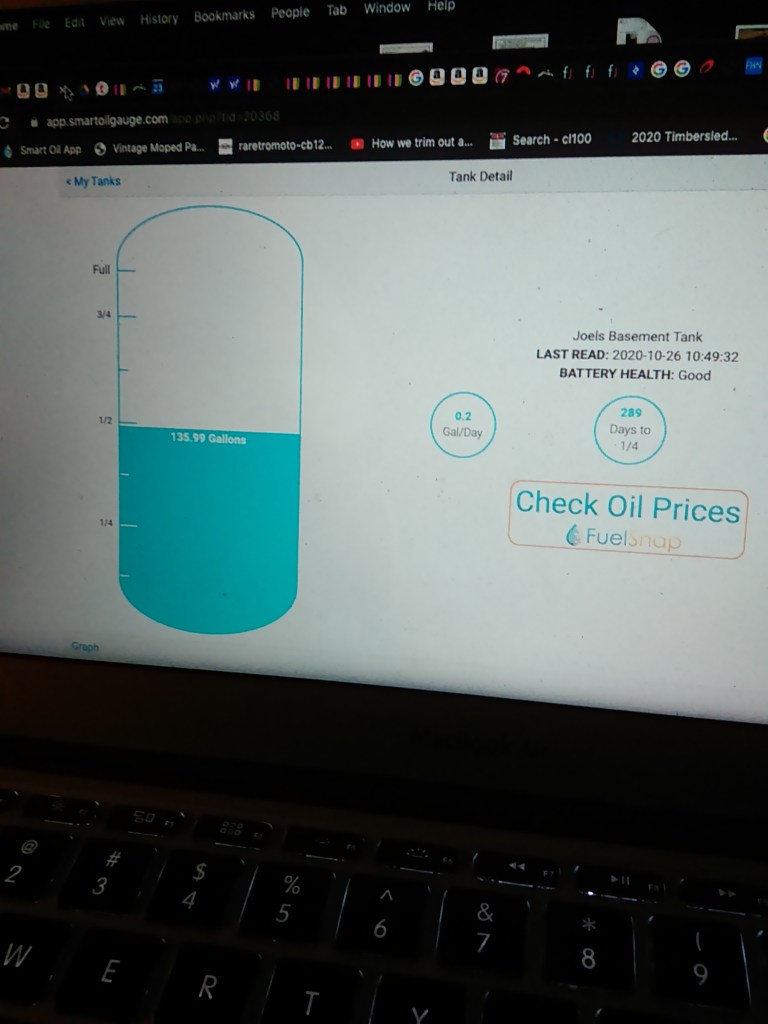

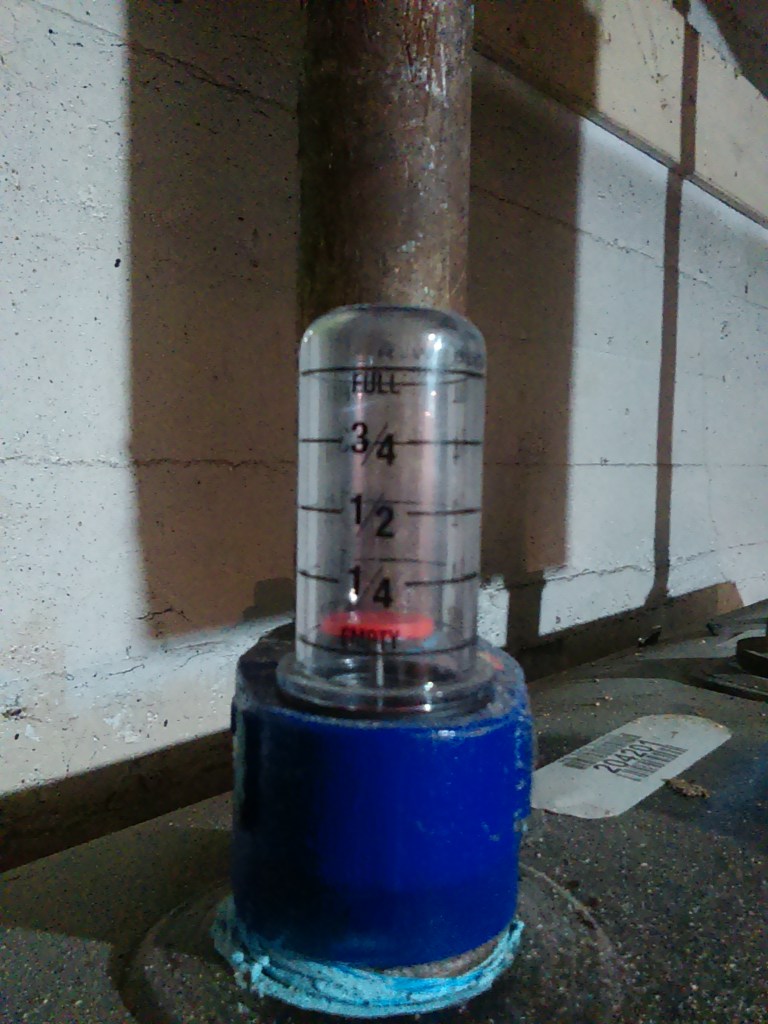

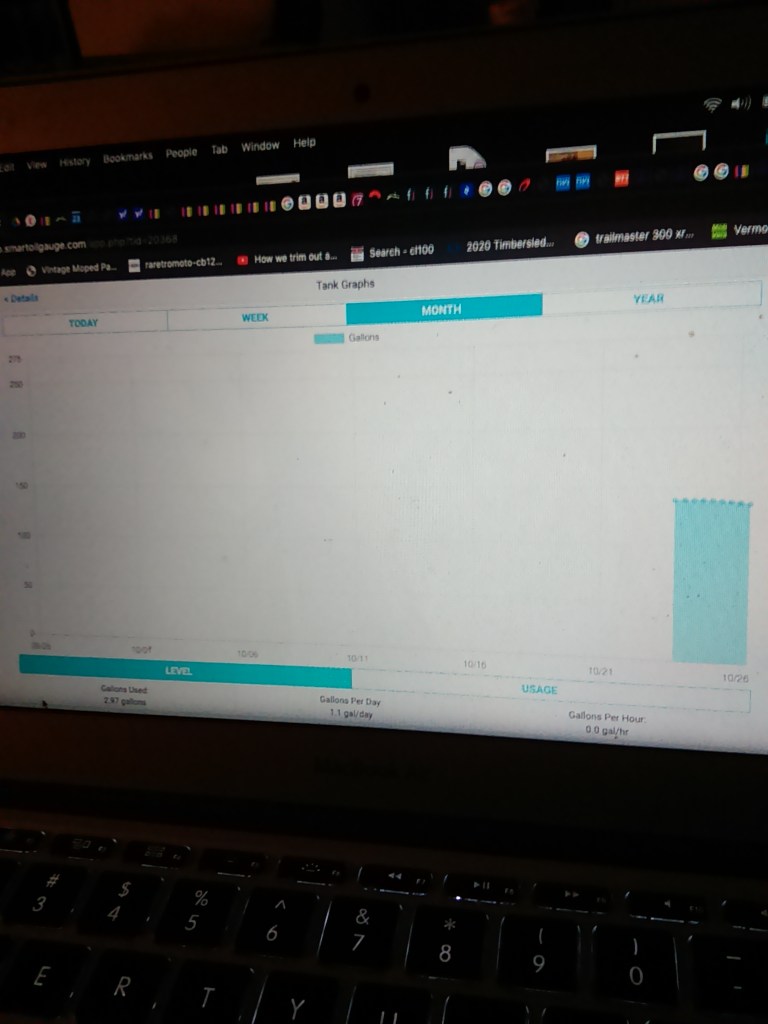

Down in the basement- prepping for the heating season- the oil furnace has run a few times. Last year we had a new tank installed down there. The gauge was way off. Last season I thought I was out of fuel but when the delivery guy came to fill us up he said that it only took about 1/3 of the tank capacity to fill it. The gauge again shows nearly empty, which I knew wasn’t correct, so I installed a digital gauge. The digital gauge confirmed that we were still at half tank and that the analog gauge was lousy.

It’s a pretty nice setup, was easy to install, connects to wifi, and graphs out your daily usage and sends reminders and things when you’re low and need to refill. Cool stuff.

As it got colder and the furnace ran more often it started to really stink. It was very upsetting, especially with the cold weather becoming more frequent. I started to panic a bit. The furnace was making a lot of noises and banging and stinking. Took a quick video of the damper banging away as it ran-

https://studio.youtube.com/video/6p2XGF5fT-M/edit

I finally got through to my furnace people and they said they would work some “scheduling roulette” but it still took a couple days to get back to me, and then another few days before they could come out, and I was getting worried. We had to set up the old Big Buddy heater again- reminiscent of our last winters heating experience at our rental (disastrous). It kept us in the upper 50s and low 60s but it doesn’t feel particularly safe for around the clock use.

We installed a couple more CO detectors and another fire alarm just to be safe.

We suspected that the furnace wasn’t getting enough air because of the new insulation. The heating people also came up with this same initial assessment after viewing the video I made of it running. I thought we’d need to vent the furnace to the outside for air, which probably would’ve ended up being a costly endeavor.

However, in the end, it turned out to be a very trivial fix. There is a wire that runs from the ceiling to a valve on the oil line. If the furnace catches on fire, it burns the wire which shuts off the valve so no more fuel comes in. Pretty old school stuff. Somehow the wire had gotten knocked out of position, causing the valve to close. The lack of fuel was what was causing all the horrible noises and smells. They hooked that wire back to the valve and it instantly ran perfectly. I think it was the propane guys sabotaging our oil furnace when they installed the propane lines! 🙂 (kidding of course)

Here is kind of a lousy video of our first night after moving in (its grainy)-

https://studio.youtube.com/video/Viaay4aBKWM/edit

Back at camp, we drained all the water lines and buttoned things up there. Still a bit of color in the trees. But I went back the next morning to finish up and we’d had quite a frost (20’s) and the grass was nicely frozen-

And that’s about it on the building and camping fronts. A few fun encounters along the way this month-

Turkeys! A whole mess of them in the road near camp-

I found this up in the basement ceiling. DDT dust! “Insecticide for many flowers, fruits, ornamentals and vegetables.”. Why not add that it tastes great sprinkled on your pizza, too!?!? Eesh. Nuff said.

I don’t know why, but this beer can makes me smile-

And finally, last but not least, this mouse that snuck into my office. Nothing says “hand caught in the cookie jar” quite like this photo-

Warehouse Update #12 – September 2020

This month was a bit of a mixed bag of some new stuff and just coontinued work on some older projects.

Progress continues on the bathroom and shower. It seems never-ending.

We even managed to get up a few bathroom walls and even a door (ironically, the door is on before all the walls are up). We salvaged this old door from the old building. It needs a fresh coat of paint but I like it and I like trying to recycle as many of the original materials as we can.

We decided on a dark stained board ceiling. We had lots of shiplap pine from the old attic- unfortunately most of it had a coating of cement on it. The prior owner thought the boards had a previous life as concrete forms. I spent several hours outside with the pressure washer cleaning them up. Some couldn’t be spared but the majority cleaned up well. We still have a massive stack left, didn’t even put a dent in them. We stained up a few different colors just to verify the dark looked best but stuck with the decision after seeing it. Jen rolled up her sleeves and went to town staining and varnishing all of the boards. It was very time consuming but they came out looking great.

We also got our propane tank installed. The owner of the place mentioned that we could save a little if I dug the trench and it was a nice sunny day so I knocked it out. There used to be train tracks right along the back of the warehouse- right where I needed to dig the trench- so it was rough going. Lots of hard fill. But eventually got thru it.

The ran lines to our hot water heater, where our stove will be, and a couple T’s over by my office area in the warehouse so that eventually I could install a Rinnai space heater or two over there. We still need to get our water heater vented before we can get it running.

On other fronts- I managed to get cranking on Heman’s bike project and was able to get that back in shape and up and running. Just about everything was overhauled, upgraded and cleaned. New shocks, sprockets, tires, cables, switches, lights, seats… He was able to ride it over to his father’s place and some of the family came by to check it out. He had a smile from ear to ear and couldn’t say thanks enough. Unfortunately, his father passed away a couple of weeks later. I’m glad I could have a small part in bringing some smiles in those last couple of weeks.

Meanwhile, the pups continue to be old dorks…

I was out walking and this praying mantis jumped right up on me! One of Jennie’s friends says they’re good luck.

And, to round out the month, I found this most interesting advertisement in the local paper-

So many questions here…

First, the greased pig contest. Age groups 5-10, 11-17, and “older women and men”. “Older”, like 18+? Or, like, middle-aged? Very ambiguous. It must be 18+ because mixing middle-aged men with catching greased pigs could probably lead to some heart attacks.

Secondly- “Mud Wrestling: Women Only”. Does that mean that only women are wrestling? Or that only women can attend? “Ages 18-30”, again, same question- Spectators? Or participants?

Man, this ad is a real gem.

Warehouse Update #11 – August 2020

Well, here it is Oct 26th already and I’m just getting around to finally adding the Aug & Sept entries. My primary motivator is that soon it will be Nov and then I’ll be three months behind, so I suppose I should get a little caught up.

First, I have no doubt folks have been anxiously awaiting an update to the front porch. Ed and I framed and wrapped that up tight. At present, it feels like it was about 100 years ago. The sun was out, the air was warm… I digress…

Got it frame up and put a metal roof on a couple weeks later. It’ll have a door on each end- one to a future porch where we’ll put the grill and maybe dog ramp, and the other to the dock area. The doors and windows have been sitting in the porch for several weeks while we try to button things down in there. My neighbor Heman said the other day “Man, you ever going to put those doors in? I’ve put in a lot of doors- I can help you put it in if you need help.” Good old Heman. Unfortunately, it’s a time thing, and not a help thing. More pics, less words-

Another nice addition was the replacement of the rickety old front steps that we tacked up temporarily. Someone was just going to get hurt and they needed and upgrade.

However, the whole operation did not go smoothly. I poured a small concrete pad for the stairs but was apparently having a bit of a rough mental time calculating square footage. The pad was 1’x4′, aka 4 square feet, the math couldn’t be easier there. That’s where my mental capabilities began to break down… I looked at the bag of concrete and it said for 2 square feet you needed one bag. So I thought to myself, “2’x2′ is 2 square feet” and 2×2 equals 1×4, so I just need one bag of concrete. Well it turns out that 2×2 is 2 feet squared, and not 2 square feet. If you can believe it, I did actually have math as a second major in college, despite eventually dropping it. Scary. I can only guess that it was because I was stuck at the Home Depot and just wanted to get the hell out of there that I couldn’t do basic math any more.

So the pad came out a bit low. Then I tried to pad it with some extra thinset that I had from the tile. I made that way too soupy, dumped it all in, and made probably a bad situation worse. On top of all that, I must’ve bumped the form (or just never aligned it properly to begin with) because it came out all crooked at the base. The concrete screws I had sucked, they were way too small. Thankfully I drove some Timberlocks down into it and things tightened up (love the Timberlocks)..

But, in the end, it all dried out, its fairly sturdy, and I guess I can pile some gravel around the base to hide the fact that its crooked. I’m over it now, and moving on.

Man, WordPress is REALLY fighting me today. Cmon WordPress, do your job…

We also got our washer and dryer walls up and the units installed and plumbed in. This was a huge step. No more laundry mats- I think Jennie was pretty happy. We still only had the cold water running to the washer but it sure beats the ‘mat.

And out new tankless hot water heater arrived, a propane unit. Presently we have no propane so that’ll be a whole new endeavor. I wanted to go tankless and my initial research showed that we could do electric tankless but I guess I didn’t read the fine print for cold climates and how much power we’d need. It takes like a 4×50 amp breaks and a 150A panel and the gallon per minute temp rise I hadn’t realized was only for like a 35 degree temp rise which isn’t going to cut it in Vermont. Anyway, on the plus side, once we get the propane running we’ll be able to have a gas stove which I really wanted- I can’t stand electric ranges.

As you can see we got the very fancy “WI-FI READY” model, so that you can see right there on your phone that your hot water heater is making hot water. “System Status: Heating Water”. In all seriousness I don’t really know what you do with the wifi part of it but I guess people like that kind of thing.

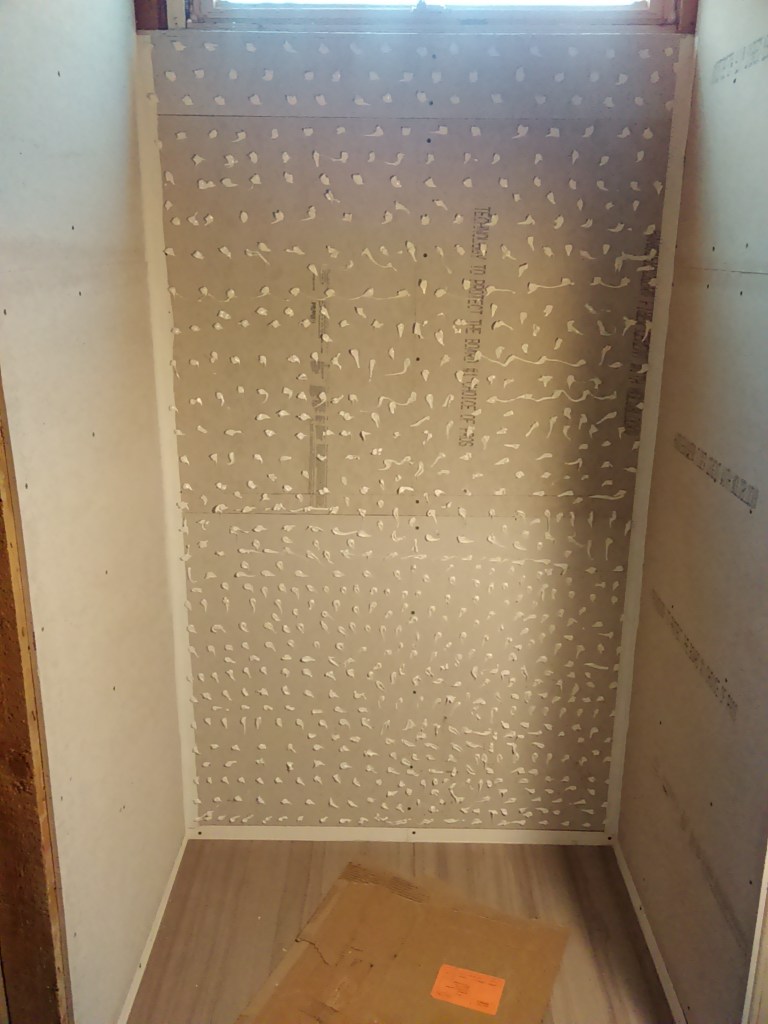

Another big leap forward was work on the shower started. We heard about this product called “Flexstone” and found it online. Jennie wanted a tile shower but I’d never done one before and it sounded like a lot of work that I didn’t have time for. The Flexstone looked nice and sounded like an easier to install alternative. In retrospect, I probably didn’t save any time. It went in fairly easily but it was very tedious and every cut had to be perfect. Lots of measuring and stressing. I think grout would’ve offered a bit more forgivess in a few areas than all the perfect cuts. But good progress was made overall in the month on it.

I think that covers the big stuff. On the motorcycle end of things, my neighbor Heman brought over his father’s CT90 for me to work on. It had been in storage for decades and not running. His father was in his 90s and in poor health, and he wanted to be able to ride it over to his fathers and see the look on his face and remember when they rode around on it toghether when he was just a kid. It definitely needs some TLC, and I’m not exactly flush with spare time these days but I’m going to do my best to get this thing back on the road. That carb is what you might call just a wee bit crusty…

Just before the COVID hit I purchased some bikes from Pennsylvania. The guy had been storing them since around March and said it was time to pick them up. So I made a stright shot down there and loaded them up by myself and cruised back. About the most contactless 10 or 11 hour round trip a person could make I think. Just one stop for gas.

And then back at camp- more pups, more beautiful scenery, and a quick visit from Champy (our Lake Champlain “”Loch Ness Monster”). The nights are getting colder and the morning fog is rolling in more regularly.

Warehouse Update #10 – July 2020

July began with a bathroom remodel. Sending this old nasty toilet out the back door was a happy moment-

We wanted dark tile flooring in the bathroom. As you may have seen in previous months images, the sub floor is VERY thick – 3″ wood planks covered in 1″ thick hardwood flooring. So, my genius idea was to remove the hardwood layer and drop the floor down an inch so I could add Hardibacker plus the tile which would bring it all out level again. In theory, this was an amazing idea, as my ideas often are. The outcome, unfortunately, was not as expected.

After expending a tremendous amount of time and energy and using just about every cutting tool that I own in some capacity, the hardwood floor layer came out:

Unfortunately, things weren’t quite as expected underneath.

While the three inch thick planks are incredibly strong, on their own and without anything tying them together they are very springy as you walk on them. This was further compounded by the fact that there are no joists underneath. There is just a span of about 10′ of planks with basement wall at one end and then a massive beam at the other end, which you can sort of see in this pic, maybe:

The hardwood flooring tied this all together and made it very strong. Removing that made it into a springboard, like planks on a scaffolding.

So, after removing all that, I needed something to tie the planks together again and sturdy things up for the tile. Ended up laying down plywood (which is stupidly expensive right now) to build the floor back up like this before I messed with it:

Followed by 1/2″ Hardibacker cement board to give the tile a nice sticking surface:

Followed by tile, a 12″x 24″ black slate that has some really nice natural features and patterning:

All finished laying down the tile:

Grouted and cleaned:

We later added three coats of sealer, and that really made things pop:

Next was the plumbing. We had a old galvanized drain that was coming out. I substantially underestimated the weight of this and thankfully when it came down it didn’t kill me, crush me, or mash a foot:

Temporarily capped that, and then back to the bathroom to install our new toilet. Thankfully, we found a unit capable of flushing 7 billiard balls, because you just never know when that might be necessary:

It all looks pretty high tech in there and I certainly hope I never have to replace the flapper (if there even IS a flapper in there):

The toilet is in:

Happy day! We’ve been without for about two weeks now.

Plumbing updates follow:

Additionally, the old vent stack was galvanized, making it very hard to tie into. It was also coming up through the bathroom floor a couple inches away from the wall where we wanted to add a second sink. So this old metal vent was removed, replaced with PVC, and relocated back into the wall where it would be hidden from sight and not in the way (blue is old, white is new):

Next came the sink. It has a cold water supply line and drain down through the floor but isn’t yet fully tied into the drain – and no hot water yet:

Installing the faucet was miserable. It was way overly complicated and my stupid hands wouldn’t fit in the tiny spaces in the rear of that pedestal sink. There may have been a lot of shouting at inanimate objects that day.

Speculatively, I may have first installed the faucet base backwards, so that the lever that closes the drain was in the front. I may have then uninstalled the entire thing and flipped it around only to discover that the handle would now no longer even go into the unit. I may have then ended up throwing that lever in the trash. This may have all led to further shouting and swearing. Again, this is all speculation. There were no witnesses. It may, or may not, have gone down like that.

After getting all those miserable main bits in place, it turns out that the handles wouldn’t even fit next to the faucet – the bases were too wide. Aren’t all sink faucet and handle holes a standard size and spacing?!?!? At this point, I was too far in and everything was covered in plumbers putty and sweat so a return to the store was doubtful. I had to get out the Dremel and do some careful grinding on a brand new over-priced overly complicated faucet set. It ended up turning out pretty good-ish and if you didn’t know you’d probably never notice – but it made something that should have taken 5 minutes to install take several hours:

After this I finally got my first order of siding to do the board & batten siding. It’s enough to do the front plus a little extra. I order through Phil’s Mill in Wells, VT, where I had gotten some lumber over the winter for the loft and other beams. It’s a good place to work with and they do a good job at a good price. This order was delayed a bit but it was no big deal as I still had work to do before I could start on the siding:

Apparently, the spacers between wood in a pile like that are called “stickers.” I knew it needed to be stacked like that to dry but didn’t know the lingo of the wood trade. In a spaced pile like that, it’s called “stacked and stickered.” When the owner delivered the wood, he asked me a few times if I had, or needed, “stickers.” I think he finally understood by my puzzled look and lack of response that I fell into the “needed” category. I was thinking “Dude, I need wood from you, not stickers. What am I going to do with stickers?” Moving on…

That weekend we went to visit Jen’s mother. She was looking to clear out some items and we got to pick some of the old buildings and areas that were previously minimally accessible. We found lots of fun items like old wooden crates, wooden pulleys and block and tackle, a wire spool, and Thor’s hammer. We also picked up a bunch of old barn board and wooden doors to use for interior trim and some furniture building, as well as an old sheep pen to corral the doggies:

Back to the building… One fairly significant obstacle to putting up our new siding on the front of the building is that the front porch is not yet constructed. Finally needed to quit putting that off and get to work.

Ripped out the old staircase and had to relocate the dog ramp to the front of the loading dock:

The area where the stairs were located needed to be filled with some matching timbers to meet up with the porch. I believe these are those same 3″ thick boards used in the flooring inside, and they’re not something you can just go out and buy at the local Home Depot. THANKFULLY I found some matching bits rooted away in the dirt under the porch:

Finished up that day with getting the base constructed:

The following day was filled again with lots of swearing at inanimate objects, which upgraded to ladders being hurled across the yard. Nothing seemed to quite want to work out as expected. Every detail was fighting me. Building a porch is fairly straightforward. However, cleanly tying it into an old building greatly complicates everything.

One example of these problematic details was the rightmost loading dock upright. It had been pushed out and come unfastened from the joists above it, probably under weight of snow, and it angled a bit to the right. It ended up being right in the way of where the left wall of the porch would be and needed a correction. I could come up with no good tool, item, or method to move that upright. A come-along would work well but I don’t own one. I had a boat trailer ratchet strap somewhere (the one we used in a catapult build some time ago to ratchet the ‘pult bucket down), but I looked everywhere and couldn’t find it. Nothing else came to mind. Then I remembered the wooden block and tackle that we picked in Sutton the weekend before. 1800’s to the rescue! This was just the ticket:

I needed to coax the upright on the right side about 6-8 inches to the left. I put a strap around that upright and another on the properly fastened upright to the left, connected the wooden pulleys up to the straps, and gave some pretty strong pulls on the rope to test it. It would move just a bit and I could tell it could be made to move with a little more weight than just me pulling on it. So, I grabbed the rope and jumped off the loading dock. With some groaning and moaning the old upright gently slid right back into place as I swung through the air and hung from the rope. It was a lot of fun (though probably not particularly safe) and a good way to end a day which had otherwise proved fairly unproductive.

The next day Ed came up for a couple of days to help out again. Due to work, life, COVID-19 and other factors, we hadn’t had a chance to work or hang out since the snow was on the ground. It was good to see him, and as always he was a tremendous help in getting the porch project wrapped up. With the two of us working together it probably cut the build time by a factor of four. Jen took some good pics of progress along the way. BUT, since we didn’t finish until the calendar had flipped into August, you’ll just have to wait until the next installment to see the final product 😉 (I know, the suspense must be maddening.) Until then, some porch progress shots as things moved forward on 7/31:

And that wraps up the month of July. Stay tuned…

Warehouse Update #9 – June 2020

Well it’s already August now, somehow, so I suppose it’s time I added June activities.

The big change in June was installing our air handler system. With all the spray foam work the house is buttoned up tight, and you need to bring outside air in and exhaust the inside air so that there is a constant supply of fresh air in the house. This seems a bit ironic since the point of the spray form is to keep the house tight and keep outside air outside and inside air inside. But, houses still need to breathe- hence, the air handler.

There are two types: Heat Recovery Ventilation (HRV) and Energy Recovery Ventilation (ERV). Both types exchange heat so that cooler indoor air isn’t exhausted outside in the summer, and warm inside air isn’t exhausted out in the winter. As air goes in and out, the heat is exchanged to some extent so that you’re not just blasting your house with cold outside air in the winter. The primary different with the ERV system is that it also exchanges humdity, keeping humidity levels lower in the summer and higher in the winter. We went with the ERV unit.

It’s not too exciting but was glad to get it all hooked up and running without much in the way of issues. We have the exhaust on one side of the warehome and the intake on the opposite wall, with 4″ rigid metal vent pipe running to and from the unit which hangs by flexible insulated duct work.

The floor is incredibly thick and it was challenging to get holes through for the venting. As you can see here, 4″ thick on the tape. 1″ hardwood on top of massive 3″ thick planks:

Here is the unit all finally installed and the vent and exhaust above the basement into the warehome:

We also finally finished up the indoor framing for laundry room and bedroom. Bathroom on right, laundry room in the center by the basement door, and then bedroom to the left of that:

Laundry room and basement access:

Bedroom:

On the doggy side of things, the old pups have been having a lot of trouble on the stairs so we finally built them a ramp. At first it was too steep and needed to be lowered down one step with a bit of redesign, but it works pretty well. You really need to pay attention or Mason will occasionally bumble right off the side of it:

But you’ve gotta keep these two happy or no work would ever get done without all their incredible supervision:

Back on the poisonous plants front, Joel’s battle with poison ivy rages on! We scorched the earth with weed killer and knocked it back a bit. Blasted it good on three separate occassions… But in short order it all just grew right back. Need to start wearing long clothing every time the lawn gets mowed or else this:

Amidst all this we still managed to find a little time for some non-warehome projects and fun.

Back at our camp… For years I’ve been talking about building an outdoor shower but it never seems to materialize. Seemed like getting the plumbing in place and hot water access was always a bit more work than I had time to tackle. But we found an outdoor heat unit that hooks up to a portable propane tank. All you have to do it run a hose to it and install a couple batteries to ignite it. It was very inexpensive and works amazingly well. Exactly what we needed to get this project moving:

I absolutely love it. Jen isn’t quite sold on it. Eh well. You win some, you lose some…

In short order, mice had built a nest in the top of the water heater unit. I don’t know how moss packed on top of a gas burner didn’t catch fire. It’s a small miracle:

We were able to enjoy some incredible weather and quality hammock time:

And even squeezed in a little fishing time with a visit from our friend Jimmy C:

Back at the warehouse, my neighbor Heman brought over a bike for me to work on (for his kid to ride) as a little side project for my “spare time” 🙂 It’s a little Yamaha PW80 that had been sitting in one of his storage units for several years. The carb on this thing looked like it had been filled with sand:

Well, that about wraps up the month of June (now that it’s August)!

Warehouse Update #8 – May 2020

Looking back, I feel like not a lot got done in May… its amazing how long it takes to get things done sometimes. I think I needed a little break after the spray foaming finally happened.

We got a pretty solid snowstorm while we were still at our rental on Little Lake-

I finally had to break down and get some scaffolding. Should have gotten this a while ago; it would’ve helped with the exterior sheathing. Live and learn. Two levels of scaffolding with a ladder on top for a guy who hates heights – what could possibly go wrong here?

Then, windows and doors. Needed to get them all in place so we could get our efficiency audit.

I also finally finished up the loft flooring. I got a bunch of reclaimed 2×6 tongue and groove spruce from a guy on Craigslist in Burlington. Somehow, it ended up being the EXACT perfect amount. I can’t believe it. I had ONE board left over. Unbelievable.

And, I managed to get a little workspace set up outside the office in the warehouse, with a decent workbench that used to be in the warehome and some worklights so I can finally see out there a bit better to work. Still need to run an extension cord to power the lights but it’s progress!

Amidst all this, our poor dog, Jack, had a sort of a stroke, called ataxia. In the morning he took a long walk with Jen as his does most every morning and everything was great, but then suddenly in the afternoon he suddenly couldn’t stand. He wobbled around like a drunk and couldn’t stand up and fell over a lot, his eye twitched all over, and his head was cocked sideways. It was a very rough time for us, we really couldn’t even think about working, and he needed constant supervision so that he wouldn’t fall and hurt himself. Mason just got sick the month before and now, Jack, even worse. I thought for sure we would have to put him down. He stopped eating and could barely walk unassisted.

Just like Mason we took him to our new Fair Haven Vet and she explained this happens sometimes to old dogs, but he can still recover and lead a productive life. For a couple weeks I was pretty skeptical with the very slow recovery, but he has made a lot of progress and is doing much better. His head is cocked much less and his balance is about 90% (as long as he stays focused) and his stamina is returning and he’s taking longer and longer walks with Jen. I can’t believe how resilient these old pups are. They’ve been such an important part of our life for the past 15 years I can’t even think about life without them.

To keep the unlucky streak going, our roof started leaking again, after paying over $1000 to get it patched. It turned out that a big windstorm had gotten in underneath the rubber roof and lifted it up over the vent pipe to make a nice little rubber tent up there, which both let water in AND blocked our drain vent-

Thankfully, Markie Roofing got here right away again and fixed us up. Just need to try and make it until Fall and we’ll probably get a new roof.

We’ll end again with some random happenings along the way to share…

Our doggy visitor, hanging out on our porch while I worked up on the scaffolding:

Unfortunately this sweet little pup got a little too interested in the contents of my truck one day when I left the windows down and it scratched up all of my truck doors. Doggy is now banned.

Notice this sealant I was using states “Professional Use Only”. I did, however, manage to get away with using it without any consequence whatsoever!

This murder hornet decided that the scaffolding was his territory and was determined to defend it. He would buzz all around my head a few feet away and every time I turned my back he would dive at me:

He was really pissing me off so I took a swipe at him with a 2×6 and sent him on a nice trip thru the air (but from which he fully recovered) and consequently smashed the other end of the 2×6 right through our brand new window screen:

Jen and I like to have a good laugh about this image on the sliding door box which shows FOUR people lifting and moving the same door that I moved and installed myself 🙂 –

A rainbow at the taco stand. If you look closely you can see the double rainbow (remember how it was just snowing a couple weeks ago???)-

The pups, supervising the sliding door stain and varnish –

And finally, poison ivy. Everywhere in the back corner. I wondered how the heck I got poison ivy in the WINTER when Ed and I were working. It’s growing right up the sides of the building, on those vines we were ripping off. You will definitely be hearing more about this- it’s WAR. Currently, however, I’m losing badly…

Warehouse Update # 7 – April 2020

For April 2020, the focus was on spray foam. Getting this work completed has been the primary driver for all of the work done thus far. Previously, installing new sheathing that they could foam up against, getting all the framing in. Now the last step is to get the wiring run and the foaming can begin.

There was a lot of wiring. Primarily, I wanted a lot of smaller lights all spread out across the ceiling rather than having a few larger spotlights. We’re also adding a number of chandelier lighting fixtures and fans. They’re all wired up separately. Because I wanted the insulation as thick as possible, I opted for individual J boxes in the ceiling so the LEDs will mount over the box, sticking out a bit, but with minimal installation depth. The other option was the deeper can-light type ceiling fixtures which would’ve created a nice flush lighting but at the expense of having thinner insulation behind those cans. Because the ceiling is insulated right up against the roof, the lighting option that protruded a bit more seemed like the way to go.

Wiring photos aren’t that exciting. Here are a few.

All of the old wiring was completely disconnected. The only wire that was in there previously that will be reused is the basement light switch and one outlet there. All of the rest of the wiring has been completely re-run. It’s not yet installed into the panel or wired up at all the boxes, but it’s all pulled to the locations it needs to be in.

Once all of the was complete, the foaming began. We chose Holmquist Builders to do the foam work. They explained things well, mentioned some things we weren’t aware of, and answered all of our questions. A crew of two guys worked just after the COVID-19 ban was eased up to allow 2-man crews back into worksites. They prepped all the surfaces, covering the important beams with plastic, set up some scaffolding and got to work. It took about a week in total.

And that pretty much wraps up April. Getting that done was a major milestone. Next on deck is getting all of the windows in place so that we can get a blower door test and receive a rebate from VT for the foam work. It only amounts to about 10%, but we’ll take what we can get!

Along the way our dog, Mason, had a rough patch where he threw up all night and then couldn’t stand up on his own. We thought maybe that was it for the old man, but he has since made a full recovery and is back to his old grumpy slow-moving self. He is about 16 years old now, so I guess he has earned the right to be as grumpy and stubborn as he wants.

We’ll end things out again with more fun (and scary!) things along the way…

Found an old bottle cap nailed to a beam in the roof:

This dog started hanging around. It just lounges around out on the porch. Everyone tells me “nice dog!” and I have to tell them “nope, not my dog.” She just shows up randomly, comes in and wanders around. This place attracts all types…

I had to clean out underneath an overhang at the front of the building so they could spray foam underneath. I saw something that I thought was an old towel or something. After brushing it off I could tell it wasn’t a towel…

It’s some sort of petrified beast. I flipped it over. GAH!

And, finally, BIRDS!!! You wouldn’t believe how many different types of birds we get coming into the warehouse. The last bird was a big woodpecker, either a northern flicker or a red bellied woodpecker. Here was one of the first to arrive-

Warehouse Update #6 – Mar 31, 2020

There was quite a gap in updates. What have we missed…

Started framing out the bathroom. Seemed a simple project but managed to mess that up about 3 times. Had planned 60 inches of width on the wall space to the left of where the bathroom would be for a washer/dryer and somehow it came out to about 55 inches on the first try. This is what happens when you work all day and then try to build in a short couple hours after work…

Ed came up to help again on the front of the building. We framed out a couple windows, front door, and removed the porch. That thing came down scarily hard, and fast.

As has maintained consistent throughout, there was no shortage of bees and animal excrement hidden away for us to find and have rain down upon us…

Then we began removing more of the metal siding and replacing with OSB sheathing on the front. We worked pretty late into the dark this night but got it all completed-

I noticed a leak in the back ceiling which was a huge bummer. We expected when we bought the place that we’d need to do roof repair but there were no leaks thru the fall and most of the winter. But once all that ice started melting it started leaking badly. After Ed left I had to get to work setting up some plastic to temporarily drain the leaks outside-

Markie Roofing came over the next day to patch me up nicely but recommended a new roof, which we’ll probably do in the fall.

And then the next day we got a massive windstorm that tore open the front sheathing and started pulling down some on the back. I have a terrible fear of heights but I anger stapled that all back into place in the freezing rain, running up and down the ladder in the wind and ice rain trying to get it fixed-

After getting the bathroom framed up I started installing the door between the warehouse and warehome. After finishing the door framing (had to widen the old door from 48″ to 60″ and beef up the existing framing) I got to the end of that day and knew I was to tired to be messing with the door but I REALLY wanted to see what it looked like in place. Needless to say, I shouldn’t have messed with it. I was removing some side carry handles and the entire door completely fell over, taking me with it. I don’t know how it didn’t explode with glass everywhere. The paint took a little damage, I had a few bruises, but the door held up surprisingly well. A little damage here on the molding around the window, there was some more where the doors meet-

But, hey, I got to see it in place! 😉

Now onto the big exterior wall. I got a jump on this by myself, there was one random really nice warm sunny Monday so I took the day off and got maybe 20%-ish of the wall done by sliding the sheathing up underneath the metal siding. It worked by holding it in place but I also got a lot of nice cuts from the metal siding- every place there was an edge or nail hole was sharp. Found lots more bees, wasps, and plants inside the walls here-

And at the end of the day-

The following weekend Ed came up (again!) to help me finish this wall up. Couldn’t have done it without him.

Shortly after that we got a freak snowstorm that thankfully didn’t leave snow on the ground for too long…

It must’ve been a sign of things to come.

Next, was the COVID-19 disaster. Things started shutting down everywhere. I had to make a number of runs to the dump and they were handing out this letter-

You have to use punch cards to pay for dropping off trash. Notice the “Please do not place punch cards in your mouth!!!”. Ugh, why would people be putting DUMP punch cards in their mouth? Gross. There’s another sign there asking people not to put dog poop and fish guts in with their recycled paper. I guess sometimes you just really have to spell things out plain and clear for people. I digress…

We weren’t able to get ALL of the metal siding off from the large side around where the electrical comes into the building. That will take some coordination with the electric company. So for now to keep moving forward towards getting spray foam insulation I put up some foam boards between the metal siding and the interior, so they can foam up against that instead of the metal siding and we can remove the siding later.

Then I needed to block off the spaces between ceiling joists above the wall that goes between warehouse and warehome. Every single one of these was a different size and needed to be individually measured, cut, and screwed into place. It took most of the day, there were at least 50 of them. Here’s a few of them with some wooden wire spool or something-

And, of course we’ll have to wrap up this post with more fun finds along the way…

Warehouse Update #5 – February 09, 2020

During this period we got out all of the old attic flooring, put in the new door near where the loft area would be, and got most of the loft area in place.

This was all of the old shiplap that was pulled out of the attic space and de-nailed for potential future reuse:

From start to finish- adding stairs and new door landing area for going between the loft area in the house over to the loft area of the warehouse:

I’m putting down some recycled spruce 2×6 tongue-and-groove planks for the flooring in the loft. The view from up there:

And then started to work on the loft area, across the top of the front wall here (above the extremely brightly lit up front door):

So you step up from the stair platform into the new loft:

We also finally got our new oil tank installed so we can turn some heat on:

Yes, we’re well into winter now and all the insulation has been removed from the place so we’re not exactly working in the comfort of warmth now. But we needed some heat to keep the incoming water from freezing up and for now we’re just heating the basement. We also ran a small vent off one of the heat return vents into the bathroom to keep the toilet from freezing. The walls of the bathroom got covered with blankets from Harbor Freight:

It’s not all that fabulous but it’s progress. And now I don’t have to drive a mile down the road to use the toilet at the Vermont Welcome Center (although I will miss their free coffee 😉 )

More fun finds along the way… This beam signed in 1962, Poultney Bldg Co:

Warehouse Update #4 – December 18, 2019

The major demo work started with removing the old fluorescent lighting and pulling down the ceiling tiles. When we first started contemplating this project we thought about extending the ceiling all the way up to the roof but it seemed like too much work and too much cost. However, after opening all of the ceiling up and looking at it and the nice large beams up there it was just too nice not to open it all open. A big open room with a nice high ceiling and loft seemed the way to go.

So, it all came down. The joists didn’t appear to be structural and the build is the same as the rest of the warehouse space. There was shiplap flooring in the attic space that had been coated with concrete (for whatever reason) and that all came out. There was no shortage of nasty mouse-terd filled insulation and that all came out:

With all of that out of there we added a loft area in the highest section and some side stairs that lead up to the loft area of the warehouse and adds a door between that section and the house section.

The stairs lead up to a platform at the same height as the loft area in the warehouse. Previously there was a small half-door that you had to step up a few feet to go through from the warehouse loft into the attic space. This would need to be removed and reframed so we could put in a normal door at the same height as the loft area in the warehouse. Before, with the beginnings of the stair platform in the house:

At the same time, winter was progressing and there were interesting things that popped up along the way. A fire truck made several laps by, with Christmas lights, playing carols as it drove along:

And I found this banner in a bag up in the old attic, completely unopened and new: